| Cellulose Insulation |

Nu-Wool Premium Cellulose Insulation Nu-Wool Premium Cellulose Insulation

This environmentally friendly, "green" insulation provides up to 40% savings on energy bills when compared to conventional insulation materials and offers homeowners the best value/ROI.

What is Nu-Wool Premium Cellulose Insulation?

Nu-Wool Premium Cellulose Insulation is an energy-saving insulation product made from recycled newspapers. Nu-Wool Premium Cellulose Insulation, with its superior thermal and air infiltration properties, is installed in both attics and walls of residential and commercial buildings.

Why choose Nu-Wool Premium Cellulose Insulation?

Longevity

Cellulose insulation has been a proven performer for more than 50 years.

Versatility

Nu-Wool Premium Cellulose Insulation has been used in every facet of the building industry; new and existing residential structures, commercial, industrial, and institutional facilities.

Consumer Value

Nu-Wool Premium Cellulose Insulation has long offered the best value/return on investment for buyers due to its ease of installation, low material cost, proven performance, and energy savings.

Non-Toxic

Toxicologist studies demonstrate no observed adverse health problems associated with Nu-Wool Premium Cellulose Insulation.

Continued Performance

Studies have shown that there is no breakdown of Nu-Wool Premium Cellulose Insulation over time in terms of fire resistance, moisture absorption, mold growth, corrosive action or paper degradation.

Acceptance by Officials

Nu-Wool Premium Cellulose Insulation has passed years of stringent testing and meets all building codes.

Resists Mold Growth

Nu-Wool Premium Cellulose Insulation undergoes rigorous testing to insure that it will not promote the growth of molds and mildew.

Acoustically Superior

Cellulose insulation is very effective as a sound control material. More....

Back to Top |

|

| Foam Insulation |

High in performance, Nu-Seal Foam is a hybrid foam insulation system that contains high biological raw material and low embodied energy. These attributes make Nu-Seal one of the greenest foam insulation systems in the market place. Nu-Seal pases all ATSM testing ofr insulation products and is a Class 1 rated insulation product. High in performance, Nu-Seal Foam is a hybrid foam insulation system that contains high biological raw material and low embodied energy. These attributes make Nu-Seal one of the greenest foam insulation systems in the market place. Nu-Seal pases all ATSM testing ofr insulation products and is a Class 1 rated insulation product.

Formulated exclusively for resale by Nu-Wool Co, Inc., Nu-Seal Foam is the best product to complement cellulose insulation to cost-effectively seal a structure's thermal envelope.

The Nu-Seal Foam Insulation system, manufactured by Natural Polymers, LLC, is the recommended GREEN alternative to fiberglass batting and other petroleum based foam products for use to insulate rim joists, knee walls, cathedral ceilings, and other difficult to spreay with cellulose insulation. More....

Back to Top |

| E-Barrier |

E-Barrier® Reflective Coating E-Barrier® Reflective Coating

Developed by Sherwin-Williams, E-Barrier Reflective Coating helps reduce utility bills for homes and commercial buildings. When applied to uncoated attic roof decking or to previously painted commercial decking, the microscopic metal particles in E-Barrier Reflective Coating help maximize energy efficiency. (Energy savings will vary depending on building materials, home location and conditions.)

E-Barrier®

- In summer, E-Barrier reflects radiant energy from the sun

- In winter, E-Barrier prevents radiant energy from leaving the building

- Reduces heating and cooling costs by as much as 15 percent (independent testing laboratory certified)

- Low emissivity (e-rating)

- Breathable coating, won't trap moisture

- Fast, one-coat coverage with minimal overspray

Product Literature (PDF 230KB)

Back to Top |

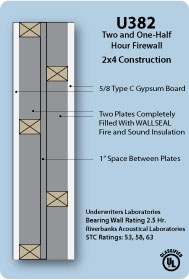

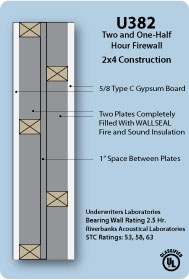

| U382 Firewall |

2.5 or 3 Hours of Full Load Bearing Fire Protection.

The U382 Firewall from Nu-Wool is an engineered wall assembly that provides the industry's highest level of protection that costs less, and saves you more. Better design, better protection for less money. And it's UL approved.

Our new U382 Firewall is a Nu-Wool proprietary design that is fully load bearing and offers two and a half hours, or three hours of protection that costs less, and saves you more than other solutions on the market.

The U382 meets all the requirements of ASTM-E-119 and UL 263. The U382 meets the requirements of shaft wall assemblies, and the independently loaded double wall assembly maintains its integrity beyond the nominal one-hour per side, giving the U382 a two-hour and thirty minute rating with only one layer of 5/8 inch type C drywall on each side. A 3-hour rating is achieved by using 2 layers of drywall on each side.

Each row of studs has a load of 10,932 pounds applied vertically to achieve the maximum working stress of wood studs in accordance with 2005 National Design Specifications for wood studs.

Nu-Wool Co., Inc. has developed WALLSEAL Fire and Sound Insulation specifically for use in the U382 firewall assembly. Green in color, WALLSEAL Fire and Sound Insulation has the same superior thermal and sound control properties of Nu-Wool WALLSEAL.

STC tests were also done on three configurations of the U382 assembly: One using one layer of gypsum board per side achieving an STC of 53. The second test added one layer of gypsum board to one side and this wall assembly achieved an STC of 58. The third test for STC added a layer of gypsum board to each side and achieved an STC of 63. More....

Back to Top |

Air Sealing

Air leakage, or infiltration, occurs when outside air enters a house uncontrollably through cracks and openings. Properly air sealing such cracks and openings in your home can significantly reduce heating and cooling costs, improve building durability, and create a healthier indoor environment.

It is unwise to rely on air leakage for ventilation because it can't be controlled. During cold or windy weather, too much air may enter the house. When it's warmer and less windy, not enough air may enter. Air infiltration also can contribute to problems with moisture control. Moldy and dusty air can enter a leaky house through such areas as attics or foundations. This air in the house could cause health problems.

The recommended strategy in both new and old homes is to reduce air leakage as much as possible and to provide controlled ventilation as needed. |

| Blower Door Tests

Professional energy auditors use blower door tests to help determine a home's airtightness.

These are some reasons for establishing the proper building tightness:

How They Work

A blower door is a powerful fan that mounts into the frame of an exterior door. The fan pulls air out of the house, lowering the air pressure inside. The higher outside air pressure then flows in through all unsealed cracks and openings. The auditors may use a smoke pencil to detect air leaks. These tests determine the air infiltration rate of a building.

Blower doors consist of a frame and flexible panel that fit in a doorway, a variable-speed fan, a pressure gauge to measure the pressure differences inside and outside the home, and an airflow manometer and hoses for measuring airflow. |

Comfort Diagnostics (Performance Analysis)

Performance Analysis resources enable Research Teams to compare the energy performance of actual houses against a standard or benchmark house. This ensures homes achieve the goals set using the systems engineering approach. Here you will find information about the house simulation protocols established by Building America. These resources are available as Adobe Acrobat PDFs. Download Adobe Reader.

Building America House Simulation Protocols

Building America Research Teams evaluate cost and performance trade-offs through a series of controlled field and laboratory experiments supported by energy analysis techniques that use test data to inform energy simulation models.

The steps involved in performance analysis include defining a reference building, measuring the actual performance of a house, and determining the energy savings. Building America developed the House Simulation Protocols report (PDF 1.3 MB) to assist in this process. This report also describes analysis procedures that provide the basis for:

Calculating the whole-house energy savings of a post-retrofit or New Construction Test Home (NCTH) relative to three important base cases: the Building America Research Benchmark, Builder Standard Practice, and Regional Standard Practice

Using building simulation analysis to calculate annual energy savings based on side-by-side short-term field testing of a prototype house and reference house

The reference building for New Construction is the Building America Benchmark building which is consistent with a 2010 home that follows the latest codes and standards.

The reference building for existing homes is as consistant with the pre-retrofit house as possible. This document gives default values for any system of the home that cannot be measured.

Comparing analyses to field-test results.

The report is broken up into three sections, New Construction, Existing Homes, and Operating Conditions.

New Construction

To track progress toward aggressive multi-year, new construction, whole-house energy savings goals of 30% to 50%, Building America developed a Research Benchmark building in consultation with the Building America teams. This benchmark acts as a reference building for new construction test houses, and has recently been updated to be generally consistent with construction practices from 2010.

Existing Homes

In addition, Building America provides a set of guidelines for estimating the energy savings achieved by a package of retrofits or an extensive rehabilitation of an existing home. This report outlines a set of typical operating conditions that will be used for the purpose of using a building simulation model to compare energy use before and after a series of retrofits are completed.

Certain field test and audit methods are also described or referenced in this report. These tests help establish accurate building system performance characteristics that are needed for a meaningful simulation of whole-house energy use. Several sets of default efficiency values have also been developed for certain older appliances that cannot be easily tested and for which published specifications are not readily available.

Operating Conditions

The operating conditions listed in the report give detailed definitions and use profiles for all end-use categories. These operating conditions apply to all simulations conducted for official Building America reporting purposes, including the analysis of both new homes and retrofits of existing homes, unless otherwise specified. |

High in performance, Nu-Seal Foam is a hybrid foam insulation system that contains high biological raw material and low embodied energy. These attributes make Nu-Seal one of the greenest foam insulation systems in the market place. Nu-Seal pases all ATSM testing ofr insulation products and is a Class 1 rated insulation product.

High in performance, Nu-Seal Foam is a hybrid foam insulation system that contains high biological raw material and low embodied energy. These attributes make Nu-Seal one of the greenest foam insulation systems in the market place. Nu-Seal pases all ATSM testing ofr insulation products and is a Class 1 rated insulation product. E-Barrier® Reflective Coating

E-Barrier® Reflective Coating